filler

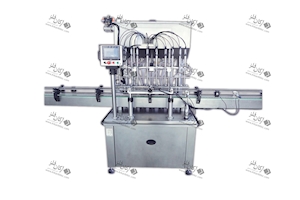

10 nozzles servo filler

کد خبر: 127

تاریخ: 1399/2/5 00:51

Suitable for different kind of thin & thick materials

10 nozzles servo filler

technical details

- Suitable for different kind of thin & thick materials from 100 to 1000 grams in one shot and 1000 to 2000 grams in two shots .

- Filling speed: 45×1 lit bottles per minute (depending on the product type)

- Filling accuracy: ±1 %

- All contact parts are made of stainless steel 316L with 1.15 to 3 mm wall thickness and the machine cover is made of stainless steel 304.

- With 4.5 meter long conveyor made of wear-resistant Polyamid

- Equipped with Servo motor and ball screw for the main motor

- With SIEMENS PLC and HMI

- Equipped with 10 stainless steel ball valve 316L + pneumatic actuators

- Adjustable filling volume on HMI

- All nozzles and machine cylinder are made by CNC machines

- The machine chassis is made of hollow profile with the epoxy paint

- Equipped with height adjustment system for different containers

- Electrical parts of power panel: Schneider (made in German)

- Sensors: Sick (made in Germany)

- Pneumatic accessories: FESTO (made in Germany)

- Equipped with drop free nozzles and automatic CIP system

- Machine cover plate has gutter for easy wash

- Machine has software definition for 5 different bottle types

- Machine is equipped with a 240 liter tank, drain valve, 10 inlet valves, electronic floater and sight glass

- Machine includes 18 months warranty and 10 years of after-sales service for an 8 hour shift

Remarks

For higher filling capacity double conveyor version is available.

| لینک مطلب: | http://en.arkanfelez.com/News/127.html |