Manufacturing Tomato Sauces and Ketchup

Manufacturing Tomato Sauces and Ketchups

Tomato sauces are used in many products including frozen foods, pasta sauces and pizza toppings, etc. A typical tomato sauce would be based on sieved tomatoes, and/or tomato paste. It would also contain water, sugar, vinegar, salt and seasoning. The desired product viscosity would normally be achieved using astarch-based thickener. Tomato ketchup is a condiment manufactured from similar ingredients, although paste is used rather than whole tomatoes. Premium quality ketchups with a high solids content derive their viscosity from a combination of water retention of the fibrous strands in the paste and the gelling effect of pectin found naturally in tomatoes. High pressure homogenization is also used to obtain the desired viscosity. This is common with lower solids content ketchups, which may also contain starch-based thickeners.

The Process

The recipe, viscosity and solids content of sauces and ketchups vary widely according to the end use. Typical process requirements are as follows:

• Mixing apparatus must be capable of dispersing powdered ingredients into water to form an agglomerate-free product.

• If the product is made from whole peeled tomatoes, these require chopping and pulping before addition to the mix.

• Insoluble particles in the tomatoes need to be fully dispersed and “milled” to obtain a smooth texture and even dispersion of the pigment (carotin) to give depth of color.

• Fibrous strands in the tomatoes must be fibrillated (frayed) to raise capacity for water retention, which increases viscosity.

• Once mixed, the product may be passed through a high pressure homogenizer or colloid mill to obtain the required consistency.

The Problem

A number of problems can be encountered when using conventional agitators:

• Additives designed to thicken the product tend to form agglomerates which agitators cannot easily break down.

• Partially hydrated ingredients can build up on the vessel wall and parts of the mixer.

• Long mixing times are required to achieve complete dispersion.

• Long mixing times are required to dilute tomato paste into water, as agitators cannot easily blend liquids of widely differing viscosity.

• A uniform pre-mix is required by the homogenizer. This is not easily achieved using agitators.

• Several runs through the homogenizer or mill may be required to obtain the desired product.

• Excessive homogenization pressure can break down fibers, damaging water retention properties, causing separation and adversely affecting colour.

• Homogenization and other handling can dull the finish of ketchups.

• Tomato pips contained in products using whole tomatoes can be crushed during milling, imparting a bitter taste.

The Solution

A Arkan Felez mixer can solve these problems and eliminate the need for additional processes such as chopping and in some cases homogenization.

The Advantages

• Dramatically reduced processing times.

• Rapid dispersion of thickeners and stabilizers.

• Improved yield of ingredients.

• Smoother texture and improved product consistency.

• Improved color.

• The product fed to the homogenizer is uniform and of a low particle size, allowing faster processing through the homogenizer and fewer passes required.

• Some sauces with low solids content may not require homogenization.

• Special “low shear” heads available for processing whole tomatoes to eliminate risk of milling pips.

• Arkan Felez mixer can be used as a “polishing step” after homogenization to improve texture, viscosity and sheen of ketchup.

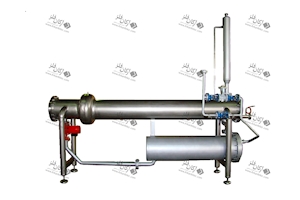

Vacumm Mixer Homognizers of Arkan Felez Company